Our unique processing technology and dedicated jigs developed in-house realize circular machining of medium ring-shaped thin materials

We have achieved circular machining of medium size (approx.φ100) ring-shaped thin materials which are difficult to be manufactured by normal methods. We use jigs specially developed in-house to eliminate generation of triangle shaped chucking distortion. Furthermore, by getting raw materials with less residual stress to thoroughly control distortion, we can perform high precision thin wall machining.

For a medium size ring-shaped material with diameter of around φ100 and thickness of 1mm, high precision and thin wall products can be manufactured only by machining without grinding

A medium size ring-shaped material is impossible to be manufactured by using only conventional precision machining equipment and chuck for reducing distortion. However, we have developed an original manufacturing method based on a new approach.

In specific, by strict dimensional control for a roughing shape before stress relieving, gapping, and finishing with dedicated jigs, we have achieved roundness of 6μm for a medium size ring-shaped material with around φ100 in diameter and 1mm in thickness.

Original jigs thoroughly eliminate generation of chucking distortion, realizing micron-order machining with high precision/high roundness

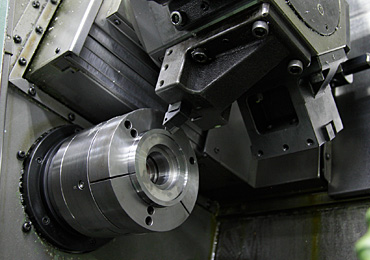

To fix work on a CNC lathe, our original jigs specially developed in-house minimize the generation of triangle shaped chucking distortion which is almost unavoidable in thin-wall machining using a conventional chuck.

To minimize stress on work and prevent chattering, work is fixed properly with original jigs, which ensures micron-order machining with high precision and high roundness.

Using our own know-hows, we relieve residual stress of process materials. Roundness is pursued to manufacture medium size ring-shaped products without strain

We have accumulated know-how of heat treatment for stress relief based on abundant thin-wall machining experiences. We consult with external specialist about a feasible heat treatment process to relieve stress with little distortion and then perform machining operations to minimize distortion as much as possible with special emphasis on accurate dimensional design as well as through.

Also, we have established unique approaches for selection and procurement of materials with less residual stress to achieve high-precision thin-wall machining without distortion.

We maintain constant temperature in the inspection room within 22°C±2°C, to conduct various precision measurements under strict temperature control.

We have a constant-temperature inspection room which is essential for high precision measurement. The room temperature is air-conditioned to 22°C±2°C. We keep products in the room for 24 hours to equalize temperature and measure a product temperature using a temperature sensor before a dimensional measurement to ensure precision measurements under strict temperature control.