Thanks to our expert engineers and excellent process planning ability, we realize machining of complex/difficult-to-machine shapes

Our expert engineers who have advanced machining skills provide appropriate process planning to achieve micron-tolerance machining. Also, we use various series of equipment including CNC lathe, and in-house developed/accurate cutters and jigs to realize precision machining of complex/difficult-to-machine shapes at a higher level than when a multifunctional machine or five-axis machining center is used.

Our qualified machining engineers and expert staff achieve advanced precision machining of complex/difficult-to-machine shapes

A number of employees have passed various skill tests including Grade 1 National Trade Skill Test.

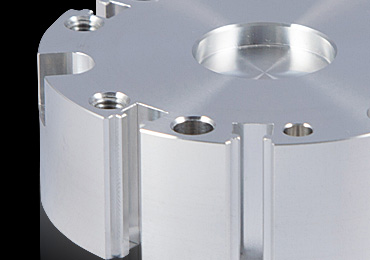

Our expert engineers utilize manufacturing know-how we have gained through parts manufacturing for more than 20 industries, realizing micron-order precision machining of complex/difficult-to-machine shapes such as eccentric processing, sealing surface/seat surface processing, and multi-axis simultaneous milling.

Appropriate machines are selected according to material, size, shape, tolerance, and other conditions. Our high-level process planning approach and high precision tooling achieve high precision machining

We use the appropriate machines based on product's material, size, shape, tolerance, and other conditions. Our high-level process planning approach and high precision tooling achieve high precision machining.

This tooling includes, for example, a convexo-concave cutter which secures surface roughness on the sealing face, deep groove milling cutter for the end face, reamer to finish an accurate multistage hole at one time. Also, a jig to set profile's position, multi-cavity jig, etc. are used to exploit the full potential of CNC lathes and machining centers.

Furthermore, a tilting-rotary table enables us to provide micron-order multi-axis precision machining with higher cost effectiveness than does a 5-axis machining center.

The best processing conditions and cutters are determined according to material and shape. We can get good surface finish of deep groove (Ra1.6/Rz3.2) in only machining process

Based on our plenty experiences in processing aluminium and stainless steel, we can get good surface finish of deep groove (Ra1.6/Rz3.2) in only machining process.

For mass-production parts, we can also conduct dry cutting for hardened steel (HRC60 equivalent) without grinding and provide 100% Rz3.2 surface roughness assurance. We minimize the indentations and achieve effective attachment/removal of products through a precision finishing process.

We can respond to mass production needs of precision machining parts used for industrial robot, semiconductor production equipment, etc. which have strict tolerance requirements.

Precision components of industrial robot and semiconductor production equipment parts (such as integration valve) involve more severe processing conditions such as micron tolerance and scratch-free surface. We can respond to these high quality requirements by scratch-free finishing and cross hole burr removal technology, while securing a perfect quality assurance system.