We have established a mass production system to respond to each major manufacturer's needs by thorough process improvement and strict quality control

For automotive pats manufacturing, we have mass production results of 90 thousand units per month. We promote process improvement by using the process failure modes and effects analysis (PFMEA) and offer 100% quality assurance by introducing the latest types of precision measurement equipment and conducting measurements with suitable inspection jigs. Furthermore, we can provide certificates, data, or other materials required for mass production.

Monthly production of 90000 automotive AT parts with roundness of 13μm and taper angle of 0.006μm 100% quality assurance

We have mass-produced 90 thousand units of automotive AT parts per month. A difficult machining processes where ring-shaped hardened steel (HRC60 equivalent) is pressed into a material, while its inner diameter roundness is kept within 13μm and taper angle 0.006μm, has been realized only by machining.

In addition, we use a coordinate measuring machine, roundness measuring machine, form contour measuring instrument, etc. to conduct strict inspections and realize 100% quality assurance.

We reduce time loss thoroughly in the manufacturing processes to establish a mass production system with shortest cycle time

We are promoting various activities to increase production efficiency such as selection of machines suitable for mass production, effective layout to control traffic flow, and a faster and smoother tool path.

By reducing loss of time as much as possible, we have established a mass production system with shortest cycle time.

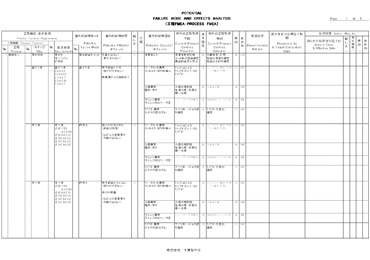

By the process failure modes and effects analysis (PFMEA), we make mass-production precision machining applicable which meets each major manufacturer's requirements

We conduct the process failure modes and effects analysis (PFMEA) which is a method to study influences of all possible failures in a manufacturing process on products and to predict and identify any errors or issues.

By considering process improvement from every angles, we offer high quality mass production precision machining which meets major manufacturer's high standards.

We can provide QC charts, process capability data, other environment-related data, etc.

We can provide certificates, data, or other materials required for mass production. We also provide a statistical evaluation report as well as a mill sheet and RoHS Certificate of Compliance.